$55.00$60.00Regular price-$5.00 offPrice

9 colors available in Auckland Local Stock & Online

<p class="MsoNormal"...

$55.00$60.00Regular price-$5.00 offPrice

19 products

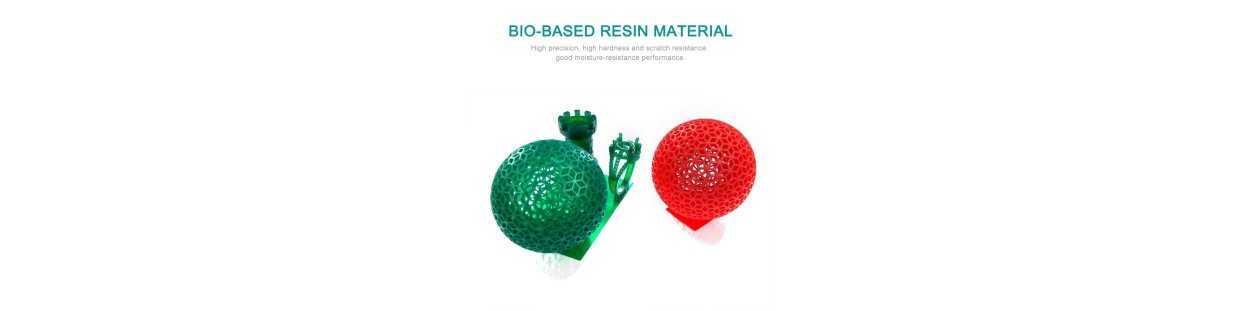

Top-quality resin consumables for LCD/DLP 3d printers. Marvle3D has various types of resin on stock, such as Plant-based (PLA PRO BIO), Water Washable resin, Hard-Tough resin, High-Temperature resin, Dental Model resin And Flexible resin.