Standard 10K resin plus is suitable for many applications. Compatible with most 3D printers on the market (405nm wavelength) <span...

$85.00Price

18 products

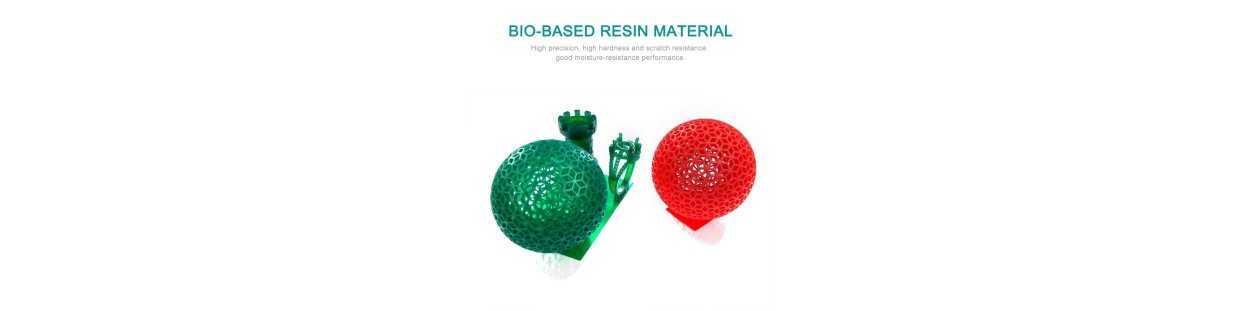

Top-quality resin consumables for LCD/DLP 3d printers. Marvle3D has various types of resin on stock, such as Plant-based (PLA PRO BIO), Water Washable resin, Hard-Tough resin, High-Temperature resin, Dental Model resin And Flexible resin.